Premium Zinc Alloy Optical Module Housings | OEM/ODM

YiXiang Precision Co., Ltd. Specializing in high-quality zinc alloy optical module enclosures, we deliver precision-engineered solutions for global clients in telecommunications, data centers, and 5G infrastructure.

With state-of-the-art CNC machining, advanced die-casting technologies, and rigorous ISO 9001-certified quality control,

we ensure superior durability, EMI shielding, and thermal management for mission-critical applications.

Our expertise spans custom design, rapid prototyping, and high-volume production—supported by a 30-day lead time and 99.8% on-time delivery rate.

Equipped with automated surface finishing (plating, anodizing) and precision tooling capabilities, we serve Fortune 500 clients across North America, Europe, and Asia-Pacific.

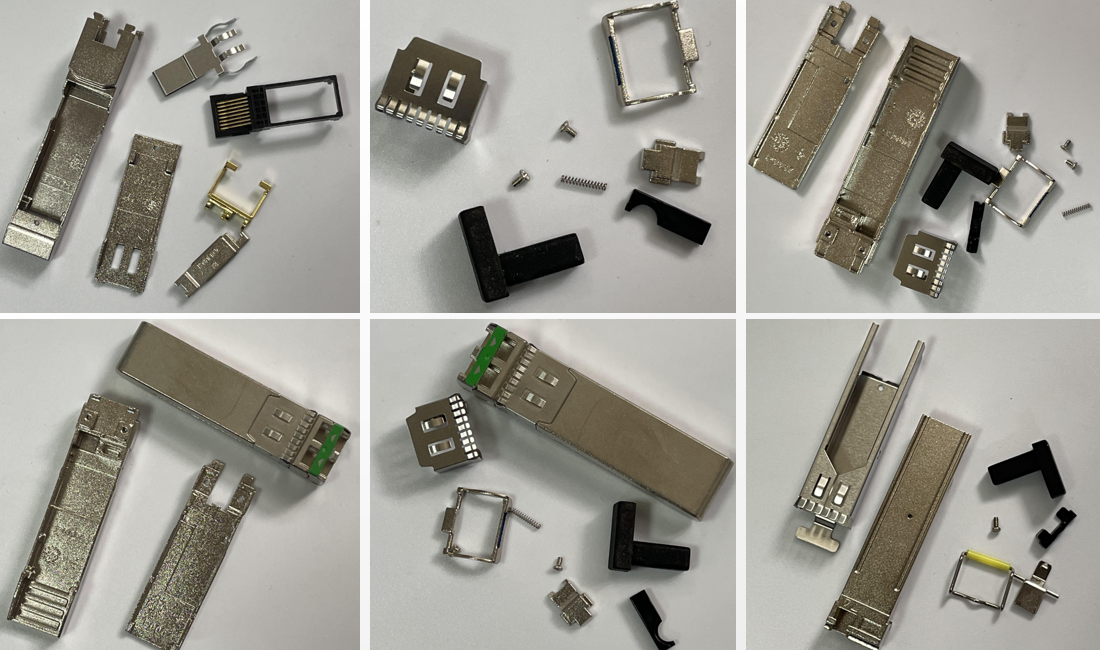

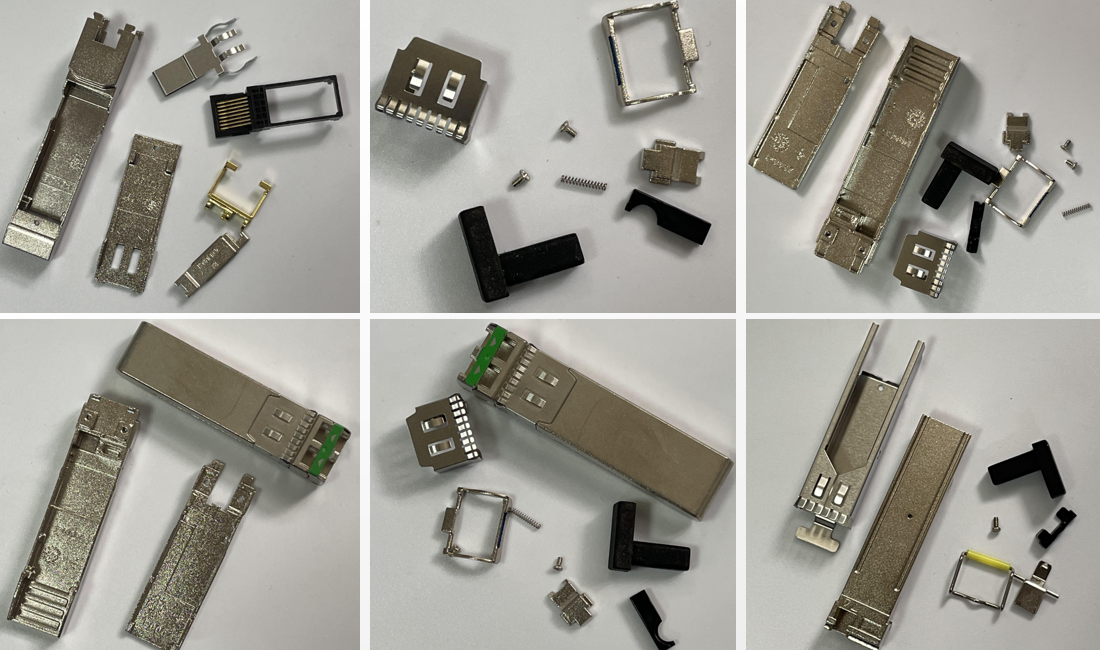

Product description:

| NO. | Name | Description description | NO. | Name | Description description |

| 1 | Model NO. | Zinc Alloy3#,Zinc Alloy5#,Zinc Alloy8#,Zinc Alloy12# materials | 10 | Production capacity | depend on complicacy of different products and the quantity |

| 2 | Production Type | Mass Production | 11 | Type of

production | Mass production |

| 3 | Process | Die casting molding | 12 | Quality control | 100% inspection |

| 4 | Surface Treatment | Blacking, polishing, anodize, chrome plating, zinc plating, nickel plating, tinting | 13 | Drawing Format | Solid Works, Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

| 5 | Machining Equipment | Machining Center / CNC Lathes / Grinding Machines /

Milling Machines / Lathes / Stamping Machines/ Full Automatic Lathe | 14 |

Company Advantage | 1. Quotation within 48 hours.

2. Quality you can rely on.

3. Zehan provides 100% satisfaction at world competitive prices.

4. We pay meticulous attention to details throughout the whole manufacturing process.

5. Rigorous QC standards, 100% inspection before shipping.

6. Strict delivery time control for each and every order. |

| 6 | Inspection equipment | Projector, Coordinate Measuring Machine, Visual Quality Standard, Roughness Tester, Hardness Tester, | 15 | Certification | ISO9001 |

| 7 | Important Tolerances

(+/-mm) | +/-0.01mm ~ +/-0.05mm | 16 | Transport Package | Standard: pearl cotton and bubble bag, carton box and seal

For large and big quantity: pallet or as per customers' requirement |

| 8 | Color | Customized | 17 | Trademark | YI XIANG |

| 9 | Origin | Dongguan, China | 18 | HS Code | 7308900000 |

Q1: What is Yixiang Precision's expertise in global exports?

A: With 20+ years of expertise in precision metal machining and SFP optical module housing manufacturing, we specialize in non-standard CNC turning & milling parts (copper, aluminum, stainless steel) and zinc alloy die-casting components. Over 50% of our products are exported to Europe, the USA, Russia, and other regions, meeting strict ISO-certified quality standards for industries like medical, aerospace, and telecom hardware.

Q2: How do you ensure quality for international clients?

A: Our 15 CNC Precision Automatic Lathe, 20 CNC machines, and 10 zinc alloy die-casting systems undergo rigorous QC inspections at every stage - from raw material testing to final packaging. We comply with RoHS, REACH, and client-specific certifications to guarantee durable, corrosion-resistant components for high-demand applications.

Q3: Can you handle custom CNC machining for niche industries?

A: Absolutely. We excel in custom CNC machining services for non-standard hardware parts, including aerospace fasteners, medical device components, and SFP+ optical enclosures. Our engineers optimize designs for high-precision, tight-tolerance requirements (up to ±0.005mm).

Q4: Why choose Yixiang for zinc alloy die-casting solutions?

A: As a top zinc alloy die-casting manufacturer in China, we produce SFP/XFP/QSFP+ module housings with superior EMI shielding and thermal stability. Our high-pressure die-casting (HPDC technology ensures cost-effective, high-volume production for 5G/telecom infrastructure clients.

Q5: What industries do your precision parts serve?

A: We support LED lighting, wire rope accessories, medical implants, aviation fittings, and fiber optic communication systems. Our multi-axis CNC machining capabilities cater to low-volume prototypes and large-scale OEM/ODM orders.

Q6: How fast is your lead time for export orders?

A: Standard orders ship within 15-25 days, including ISO-compliant documentation and hassle-free logistics to EU/US ports. Expedited services are available for urgent OEM projects.

Q7: Do you offer competitive pricing for bulk exports?

A: Yes. By leveraging automated CNC machining and economical zinc alloy die-casting, we provide high-cost-performance solutions without compromising quality. Request a free quote with volume discounts today!

Q8: Are your products compliant with EU/US regulations?

A: All exports meet CE, FCC, and REACH standards. We also provide material traceability reports and full-dimension inspection certificates upon request.